Recently, on the occasion of the 10th anniversary of LVD (Huangshi) CNC Technology Co., Ltd., our General Manager was interviewed by the magazine Sheet Metal & Fabrication. The full interview is provided below.

Amid the wave of China's manufacturing industry transitioning toward intelligence and sustainability, the sheet metal processing equipment sector is undergoing profound transformation. In this highly competitive landscape, LVD (Huangshi) CNC Technology Co., Ltd. (hereinafter referred to as "LVD"), as a key strategic presence of the Belgium-based LVD Group in China, has carved out a unique path of high-quality development with its deep technological expertise and unwavering commitment to excellence. On the occasion of its 10th anniversary, Sheet Metal & Fabrication magazine engaged in an in-depth conversation with Mr. Zhang Zhihai, General Manager of LVD, to explore how the company has broken through in an intensely competitive market and earned the trust of global customers with its solid capabilities.

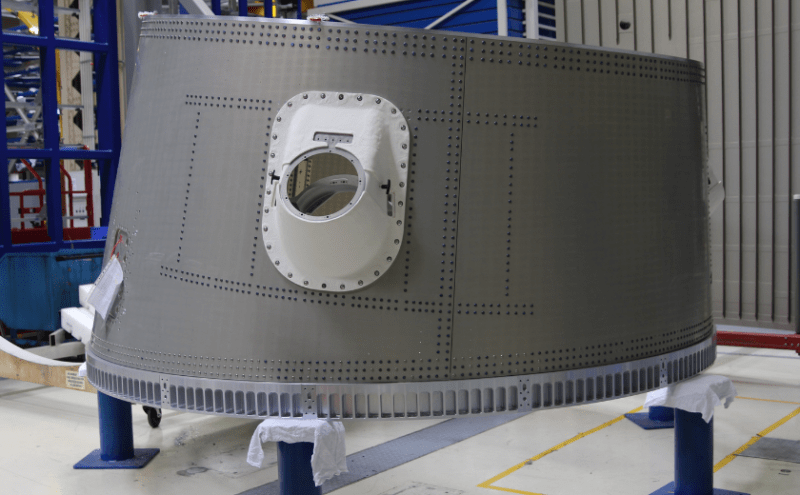

Exterior View of the Factory

Technology at the Helm: The Management Philosophy of a "Technologist"

The character of an enterprise is often closely tied to its leader. Zhang Zhihai, General Manager of LVD, is a "technologist" who has been deeply rooted in the sheet metal equipment manufacturing industry since his graduation from university. With over two decades of technical experience, starting as a grassroots R&D engineer and actively participating in the technological evolution of multiple generations of sheet metal processing equipment, this journey has shaped his pragmatic and hands-on management style.

At LVD, our first principle in decision-making is technical feasibility, the second is process stability, and only then comes commercial return,” said Zhang Zhihai. “I prefer to discuss the true advantages of our products from the perspectives of core principles, process precision, and quality control.” This technically grounded background ensures that LVD’s management decisions consistently revolve around product strength and innovation, steering clear of impulsiveness and short-sightedness.

Under his leadership, the company has fostered a shared understanding: products that genuinely address user pain points are always the most scarce resource in the market.

A Decade of Journey: From a Chinese Factory to a Global Manufacturing Pillar

Since its establishment in 2015 and the integration of LVD Group’s decades-old trading company in China, Evitec has experienced a pivotal decade. "Looking back over these ten years, we are grateful for the trust and choices of our customers. Serving them has not only strengthened our capabilities but also fueled our growth," Zhang Zhihai reflected on the company’s development journey. Evitec’s growth trajectory has closely aligned with the upgrading of China’s manufacturing sector: the period from 2015 to 2019 was a phase of solidifying foundations, during which Evitec focused on technology absorption and capacity building. After 2020, Evitec entered a fast track, achieving rapid and consistent growth in sales revenue and profits year after year.

Today, Evitec has evolved from initially offering only laser and punching machines to becoming a comprehensive solutions provider, expanding its product range to include press brakes, software, and automation equipment. Its customer base has also successfully extended from the domestic market to over 30 countries and regions, including Europe, Southeast Asia, and the Middle East. More importantly, it has transformed from a local factory into an indispensable manufacturing base within LVD Group’s global operations. "We adhere to the same design philosophy, manufacturing standards, and quality systems as LVD’s headquarters. The quality and performance of our products have gained widespread recognition from both the group’s headquarters and global customers," Zhang Zhihai added.

A landmark event in this transformation was when press brakes, laser cutting equipment, and punching machines produced at Evitec’s Huangshi factory began to be sold back to the European market. This milestone signifies that high-end sheet metal equipment manufactured in China has gained acceptance in developed markets. To date, more than 50% of Evitec’s products are exported overseas, and this proportion continues to grow.

Product Matrix: Tackling Industry Pain Points with Tiered SolutionsDrawing on over 70 years of industry expertise from the LVD Group, Evitec’s product line planning demonstrates exceptional strategic foresight. Rather than pursuing a single hit product, the company clearly segments its offerings to precisely meet the diverse needs of different customers. This "pyramid-style" product structure ensures broad market coverage while maintaining technological leadership across all levels.

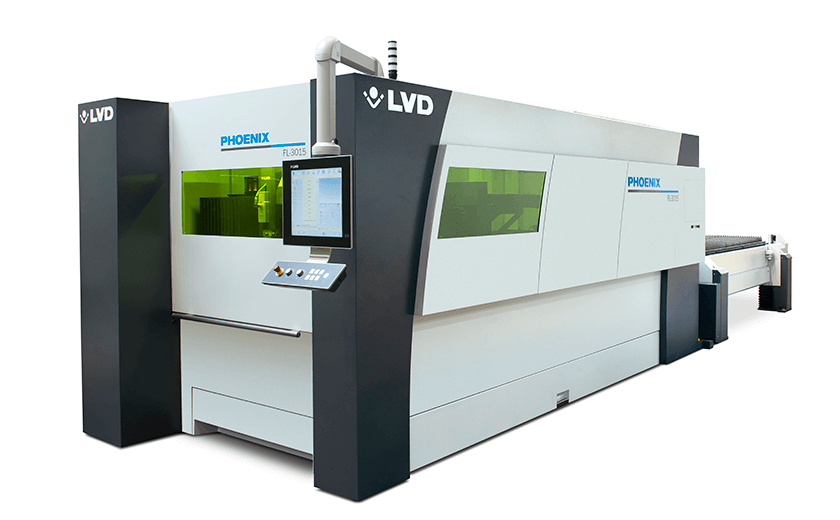

Laser Cutting Machines

LVD has been deeply engaged in the field of laser cutting for over three decades, consistently driving the industry forward through technological innovation. As early as 2015, when the domestic fiber laser industry was still in its nascent stage, LVD foresightedly launched the ELECTRA series of fiber laser cutting machines, achieving a breakthrough in 2G acceleration. This equipment has been operating stably in the domestic market for over a decade, excelling in both speed and precision to this day, making it an early benchmark in the "high-speed machine" category.

Amidst the increasingly fierce domestic competition and growing product homogenization, LVD remains committed to its strategy of technological differentiation. Through continuous investment in research and development, the company has successively introduced three flagship series—Phoenix, Puma, and Taurus—which not only comprehensively enhance bevel cutting capabilities but also offer highly modular designs to flexibly address diverse processing needs. Additionally, in response to cost-sensitive market demands, LVD has launched the cost-effective Laser Two model, thereby building a comprehensive product matrix that caters to users across multiple tiers.

All equipment is equipped with standardized automation interfaces, allowing seamless integration with LVD’s self-developed smart material warehouses and loading/unloading systems, as well as compatibility with third-party devices via protocol support. This empowers customers to smoothly upgrade from standalone operations to fully integrated production lines. This systemic capability is precisely the technological moat LVD has built to thrive in the fiercely competitive market.

Punch Presses

LVD has developed a "dual-track solution" comprising both turret punch presses and single-head punch presses, comprehensively covering diverse processing needs—from economical models to high-efficiency, high-speed configurations.

In the realm of turret punch presses, LVD has built a complete three-platform matrix:

The P Series (entry-level), addressing basic processing requirements;

The M Series (mid-range), balancing performance and cost-effectiveness;

The V Series (high-end), delivering superior processing capabilities and precision.

All series can be rapidly adapted to various sheet metal processing techniques, ensuring flexible responsiveness to customer demands.

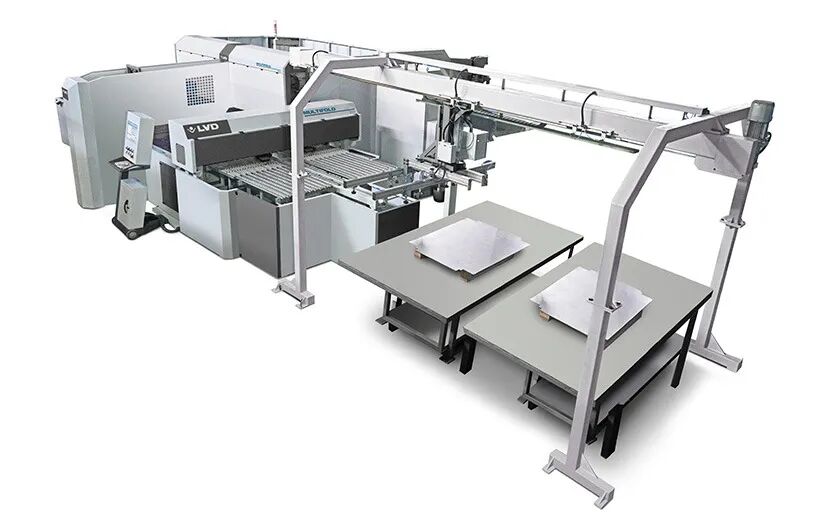

Representing the single-head punch presses is the PX Series, which not only performs punching and forming but also integrates bending capabilities. Its tooling supports 360° free rotation, significantly enhancing processing flexibility and complexity. Building on the PX Series, LVD innovatively introduced the PX-L Laser-Punch Combination Machine, which achieves highly integrated laser cutting and punching processes within a single unit. This dramatically improves processing efficiency while meeting customer needs for handling complex techniques.

Furthermore, LVD provides end-to-end solutions—from standalone configurations to fully automated smart production lines. All equipment supports third-party automation interfaces, enabling seamless connectivity with external automation systems or integration with LVD's proprietary automation devices and central material warehouses to form a holistic production ecosystem. Combined with predictive maintenance systems, LVD empowers customers to build highly flexible, intelligent, and sustainable manufacturing capabilities with lower upfront investment.

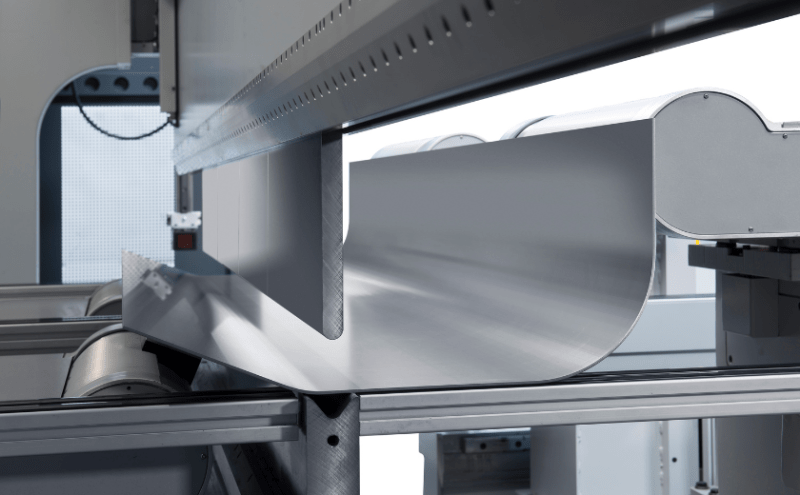

Decoding Core Strengths: How Press Brakes Became the Market Leader

Press Brakes

Bending is a critical and complex process in sheet metal processing, where variables such as material springback and thickness variation can impact final precision. Evitec’s press brakes have established market-leading positioning through two core technologies. For over thirty years, LVD has been deeply committed to the laser cutting field, consistently driving the industry forward through technological innovation.

Adaptive Bending Technology: Achieving "Innate" Precision

(1) The

Synchro-Form Series is designed specifically for the production of large profiles and can handle sheets up to 12 meters in length. Its adaptive system significantly reduces loading and sheet handling work through multi-axis CNC control, ensuring consistency in the bending results of ultra-large sheet arcs. Recently, LVD Group's headquarters secured a Synchro-Form order from the European Space Agency for manufacturing rocket components and became an equipment supplier for Boeing aircraft. This serves as the ultimate demonstration of LVD’s robust adaptive bending technology.

(2) The Easy-Form® laser real-time detection and correction system represents LVD’s core technological advantage in the bending field. Although similar products have emerged in the market following the expiration of patent protections, as the pioneer of this technology, LVD has maintained industry-leading precision in full-length bending angles through continuous iteration and upgrades, deep integration with LVD’s bending CNC systems, and the outstanding structural rigidity of its equipment.

This system employs lasers to scan bending angles in real time, instantly feeding measurement data back to the CNC control unit to dynamically adjust the upper slider depth and worktable deflection compensation, achieving closed-loop control. In practical applications, Easy-Form® consistently maintains bending precision within ±0.25°, setting a new industry benchmark for accuracy while significantly enhancing production efficiency and first-pass yield.

Modularity and Automation: Flexible Manufacturing for the Future

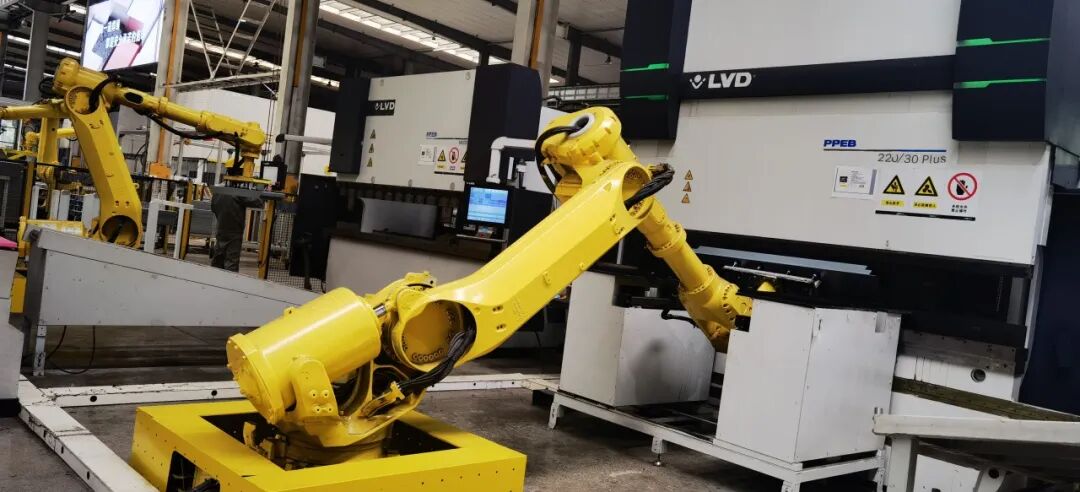

LVD’s press brakes feature a highly modular design, allowing customers to flexibly configure back gauges, tool libraries, and other components based on their needs. Building on this, Evitec offers a range of automated bending solutions, including the DYNA-CELL, Easy-Cell, Ulti-Form, and RICOBB series.

(1) The

DYNA-CELL series of fully automated bending cells.

This series secured its first order at the inaugural China International Import Expo (CIIE) and has achieved full localization in China. Its core innovation lies in the "robot calibration-free" feature: through built-in intelligent algorithms, the system can automatically identify sheet positions and dynamically adjust gripping strategies, reducing the debugging time required for traditional robot integration from several days to just 40 minutes. This breakthrough significantly lowers the barrier to automation adoption and is particularly suitable for small and medium-sized enterprises (SMEs) with small-batch, high-variety production scenarios that are introducing automation for the first time.

(2) Mobile Robot RICOBBRICOBB is a flexible mobile robotic solution that can be seamlessly adapted to various older press brakes, enabling automation upgrades without requiring structural modifications to the existing equipment. This solution provides a cost-effective intelligent pathway for traditional manufacturing enterprises, particularly suitable for customers who wish to enhance productivity while retaining their existing machinery and gradually advance their automation transformation.

(3) Inclusive and Open Third-Party Automation InterfacesLVD press brakes were designed from the outset to meet the high demands of modern production for automation and intelligence, demonstrating exceptional system compatibility and architectural openness. The entire press brake series supports optional robot integration, offering production lines high flexibility and scalability. Enterprises can independently decide whether to introduce robotic units to enhance efficiency based on their current capacity and actual needs.

Additionally, LVD press brakes can be equipped with standard automation interfaces, fully opening compatibility to third-party automation systems. This allows system integrators to easily and seamlessly connect LVD equipment, rapidly building efficient and collaborative automated production systems that help enterprises steadily advance into the new stage of smart manufacturing.

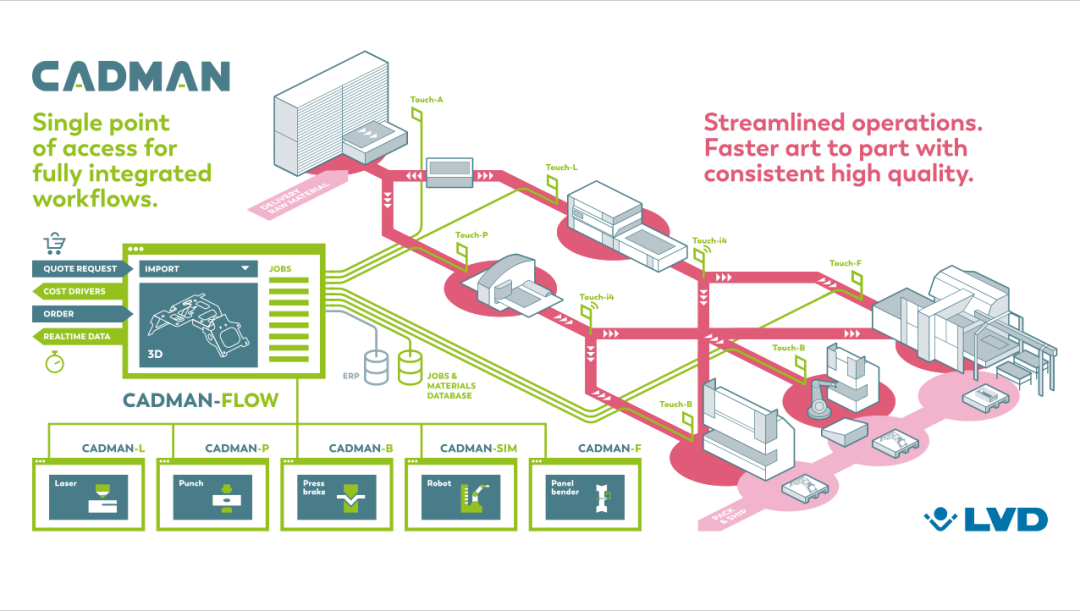

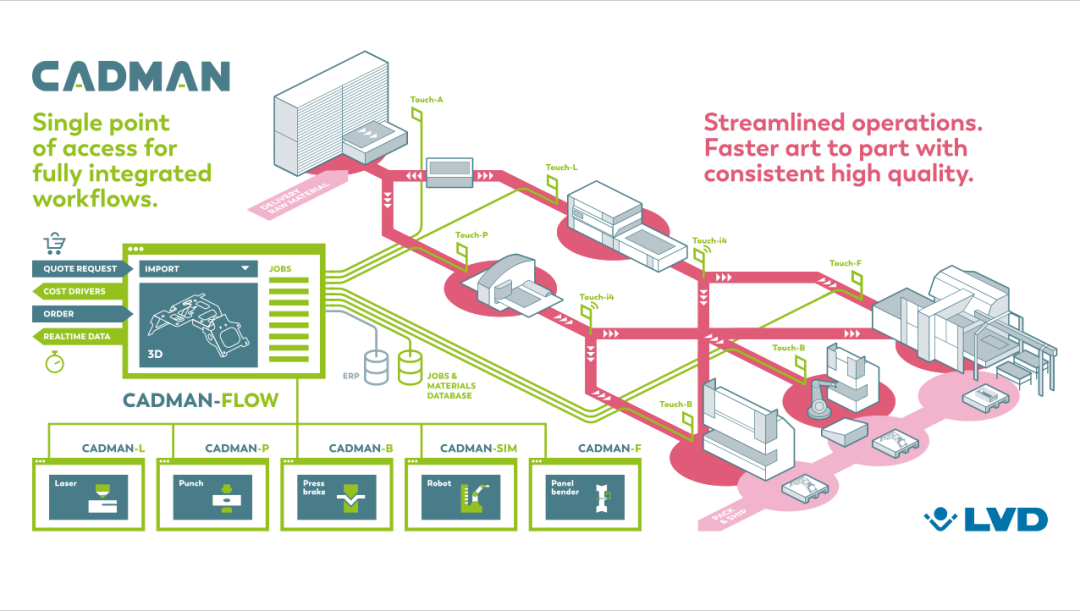

Product Matrix: Tackling Industry Pain Points with Tiered SolutionsLVD's competitiveness extends far beyond its metal machinery. Its independently developed CADMAN software suite serves as the "intelligent brain" for digitalized production. In the era of Industry 4.0, the depth of software integration has become a key indicator of the core competitiveness of equipment manufacturing enterprises.

(1) Press Brake Systems and Programming SoftwareThe software can directly generate bending programs from 3D models, enabling a "what you see is what you get" programming experience. Compared to traditional programming methods, this system reduces program preparation time by over 70%. More importantly, it supports deep integration with mainstream ERP systems, establishing a digital management framework from order to delivery. Customers can track production progress, material utilization rates, and equipment efficiency in real time.

(2) Complementary Software Such as SIM (Robot Auto-Programming) and JOB (Workflow Management)These tools make offline programming fast and straightforward, significantly lowering operational complexity. The collision detection algorithms embedded in CADMAN-SIM software allow the entire bending process to be simulated in a virtual environment, identifying and avoiding potential mechanical interferences in advance, thereby minimizing the risk of production interruptions.

The deep synergy between software and hardware creates a 1+1>2 effect. According to statistics, customers using the full CADMAN software system have seen an average increase of over 25% in Overall Equipment Effectiveness (OEE), while the training cycle for skilled operators has been reduced by approximately 60%.

Empowerment Through Experience: How the XP Center Deepens Customer Trust

With forward-looking strategic vision, LVD has meticulously established the XP Center—a product demonstration and machine software training facility at its Huangshi factory. Its core philosophy focuses on "empowerment through experience," aiming to profoundly strengthen the bond of customer trust. LVD understands that selling equipment is only the beginning of collaboration; genuinely helping customers grow is the path to long-term success. Therefore, through open-day events at the Huangshi XP Center, LVD builds a bridge for customers to intuitively experience the allure of its technology.

During these events, customers become active participants in the technological experience, not just observers. They personally operate the equipment to familiarize themselves with its performance through hands-on practice, and actively engage in software training to master advanced application skills. LVD’s professional software engineers provide guidance throughout, helping customers analyze real-world process cases and translate complex technology into accessible knowledge. By clearly comparing efficiency data before and after training, customers can see the tangible improvements brought by technological empowerment.

|

|

This innovative “equipment + training + open day” model has proven highly effective. It significantly shortens customers’ adaptation period to new technologies and equipment, enabling them to quickly apply what they have learned in actual production. At the same time, the immersive experience fosters deep emotional connections between customers and LVD. To date, the Huangshi XP Center has successfully held multiple open days, welcoming a large number of domestic and international clients, with many orders secured on the spot. This truly transforms customers’ technological investment from “visible potential” into “actionable capability,” translating into tangible production competitiveness.

Path to Breakthrough: Mastering Trends Through Innovation

Facing the intense competition in the industry, Zhang Zhihai demonstrates the calmness and confidence of a technologist: "Although the industry is experiencing severe 'internal competition,' we firmly believe that products capable of addressing user pain points will always have a vast market. The nation is vigorously promoting informatization, intelligence, and green development, which presents unprecedented opportunities for innovative enterprises."

LVD's next strategic steps are clear: on one hand, the company will continue to deepen the digitization and informatization of its internal management systems; on the other hand, it will further increase investment in research and development, planning to raise R&D expenditure to 8% of sales revenue over the next three years to accelerate advancements in core technologies such as adaptive control and intelligent software. Simultaneously, the company is actively preparing to launch a new generation of hybrid manufacturing units, which will further break through the traditional boundaries of sheet metal processing. This includes exploring the introduction of advanced foreign four-sided bending centers, among other initiatives.

Concluding Remarks

LVD's decade has been one of "technology as the foundation" and "intelligent manufacturing for the future." It has successfully embedded LVD's cutting-edge technologies and standards into the fertile ground of Chinese manufacturing, transforming robust technology into production competitiveness for customers through continuous innovation and precise market insights. Looking ahead, LVD is charting a clear path and taking steady strides to write an outstanding chapter for Chinese intelligent manufacturing in the global market. As Zhang Zhihai aptly puts it: "There are no shortcuts in manufacturing. The only pass to success is sustained innovation and reliable quality."

Source: LVD