DNE Laser: DNE Laser's D-Cell Automated Production Unit Wins the Laser Rising Star Award

On November 28, the 4th SRA2025 China Laser Rising Star Summit and Laser Rising Star Award Ceremony was grandly held in Wuhan Optics Valley. DNE Laser's D-Cell laser automated production unit stood out among numerous competing products for its advanced, efficient, and intelligent core advantages, offering a practical innovative solution for the high-quality development of the manufacturing industry. It successfully secured the "Laser Rising Star Award—Best Laser Intelligent Equipment Technology Innovation Award."

This award is jointly organized by the China Laser Rising Star Award Committee and "Laser Home," with the support of several authoritative industry institutions. It serves as a highly influential benchmark for technical excellence in the laser field. Winning this award signifies that DNE Laser's R&D capabilities and technological innovation in the intelligent manufacturing equipment sector have once again received high recognition from the industry.

I. Technological Breakthroughs of the D-Cell Laser Automated Unit

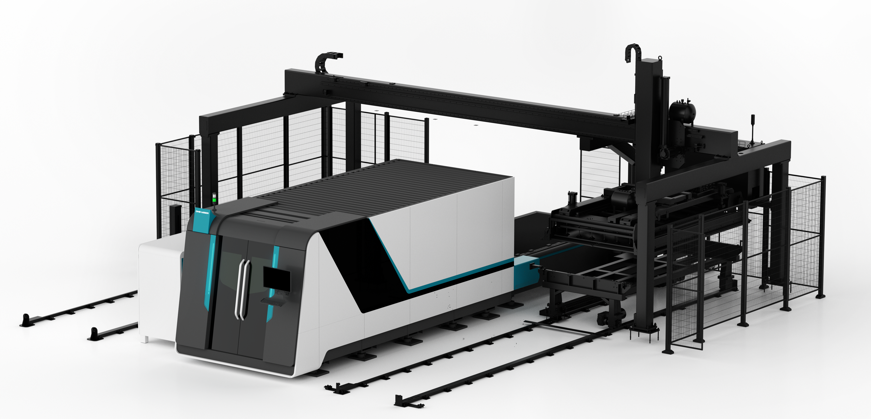

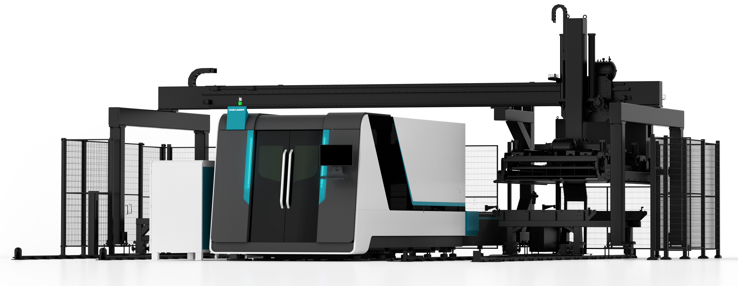

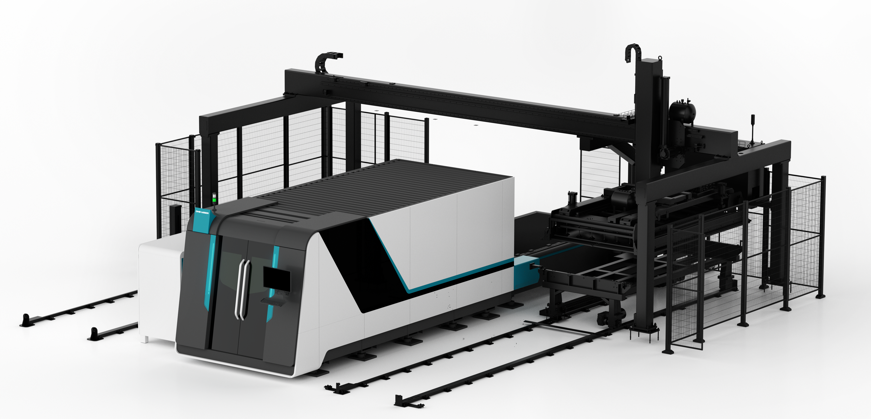

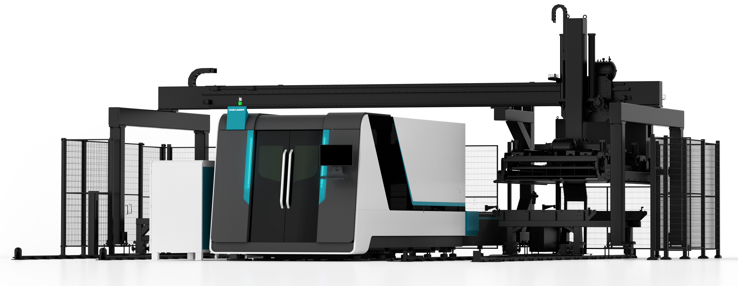

As an intelligent laser automated unit independently designed and developed by DNE Laser, the D-Cell deeply integrates Industry 4.0 technology, demonstrating outstanding advancedness within the industry. Its core advantages are reflected in three key dimensions: full-process automation, human-centric design, and flexible adaptability.

(I) Fully Unmanned Process: Boosting Efficiency, Ensuring Quality, and Reducing Costs

The D-Cell establishes a complete automated workflow, from raw material feeding to finished product offloading:

Raw materials are transported from the feeding station to the exchange area, where a vacuum suction cup elevator precisely picks up the materials (with protective forks underneath to prevent slippage) and transfers them to the cutting machine worktable.

After cutting, the exchange table automatically replaces raw materials and waste, with the elevator conveying the waste to the waste platform.

The entire process requires almost no manual intervention. With just one operator overseeing operations, continuous "automated production" can be achieved. This not only significantly improves production efficiency but also reduces labor costs and production uncertainties, greatly enhancing production stability and product quality. It stands as an ideal choice for modern intelligent manufacturing.

(II) Human-Centric Design: Balancing Convenience and Safety

In terms of user experience, the D-Cell adheres to human-machine interaction principles, featuring an intuitive interface and simple operations that allow even non-specialist operators to quickly get started. This enables "foolproof" production management, improving job satisfaction and efficiency.

Regarding safety, the system optimizes loading and unloading workflows to reduce physical strain on operators and is equipped with advanced protective mechanisms such as safety barriers and light curtains. It strictly complies with industrial safety standards, ensuring a secure production environment.

(III) Multi-Technology Integration: Adapting to Diverse Needs

To meet the personalized requirements of different customers, the D-Cell innovatively integrates advanced technologies such as magnetic sheet separation, high-precision online thickness measurement, efficient air-blowing separation, and mechanical bending. This creates a highly flexible and reliable automatic loading and unloading system capable of adapting to production needs across various scenarios, demonstrating strong market adaptability.

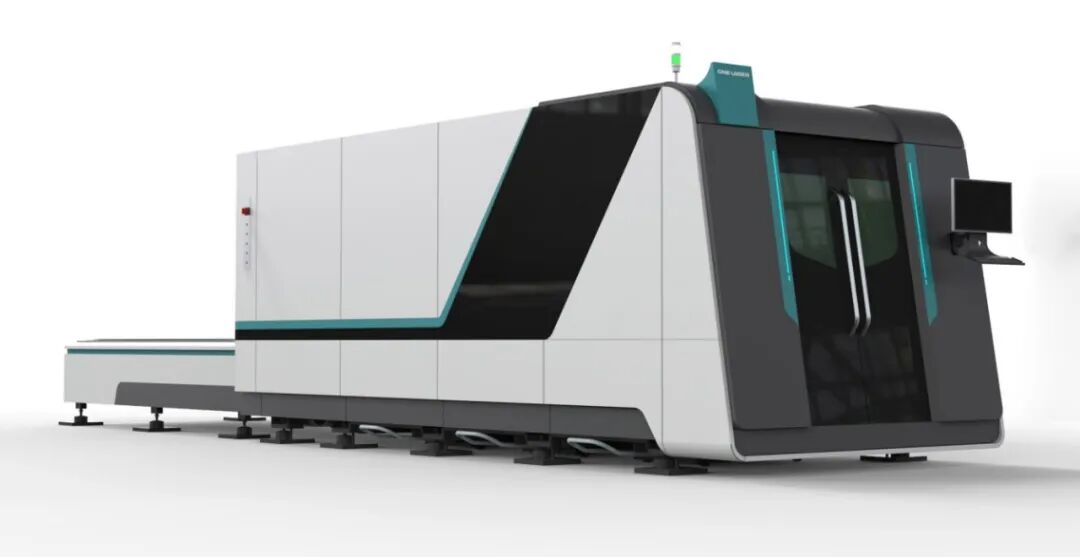

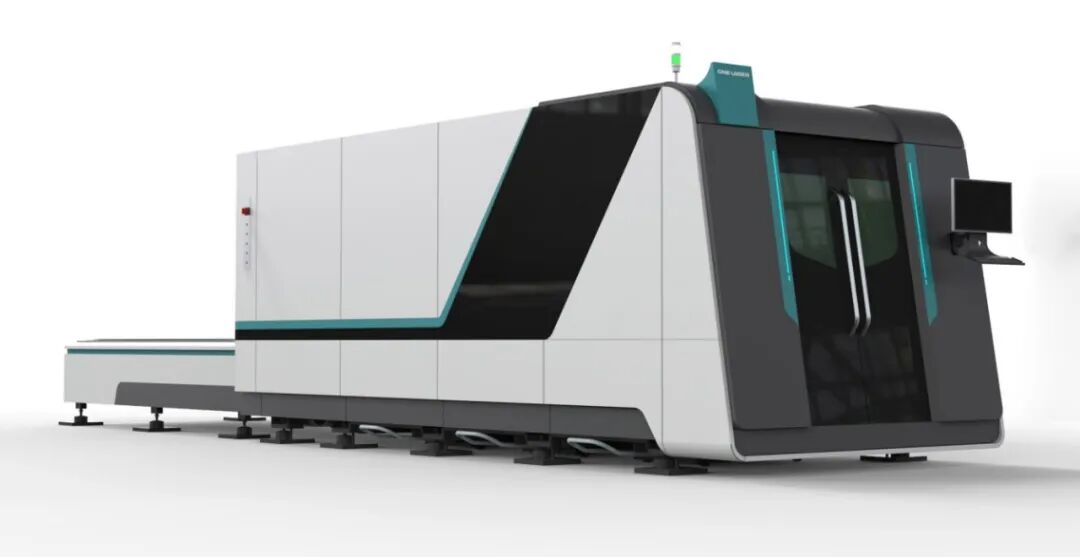

II. The Core Strength of D-Speed Equipment

As the core equipment of the D-Cell laser automation unit, the D-Speed high-performance laser cutting machine boasts industry-leading specifications. Centered on "efficiency enhancement" and "precision assurance," it provides robust support for the unit’s outstanding performance.

Powerful Performance Reserve:

With a maximum laser power of up to 20 kW (Non-CE/NRTL version) and 12 kW (CE/NRTL version), it easily handles metal plates of varying thicknesses and materials without frequent equipment adjustments.

Precise and Efficient Motion Control:

A maximum single-axis acceleration of 1.5G ensures swift and accurate motion for precise cutting, while a maximum multi-axis positioning speed of 150 m/min significantly reduces non-cutting idle time. The maximum multi-axis acceleration of 2.0G enables rapid response to commands, maintaining high efficiency even in complex pattern processing.

Significantly Enhanced Cutting Efficiency:

Through proprietary cutting head technology combined with small-core fiber, the overall cutting efficiency for 1-3 mm plates is increased by 22%. The integration of 7Hz low-pass filtering technology further boosts efficiency by 15% compared to traditional 5Hz solutions, while delivering superior cutting quality. For 1-3 mm plates, burr height is ≤0.02 mm, and cut surface roughness is ≤Ra3.2, achieving a perfect balance of "high speed" and "high quality."

III. Aligned with Industry Trends, Expanding Application Boundaries

"This award is the best recognition of our technological innovation path," stated the award recipient from DNE Laser. Currently, the market size of China's laser equipment industry has exceeded 150 billion RMB, with intelligence and automation becoming core drivers of industry advancement. The development of D-Cell precisely addresses the urgent needs of the manufacturing sector, such as rising labor costs and the demand for efficiency breakthroughs.

Currently, the D-Cell has been applied in sectors like automotive manufacturing and precision sheet metal processing, providing critical equipment support for customers building smart factories. In the future, its penetration into high-end fields such as new energy and aerospace is expected to continue growing.

IV. Deepening Innovation, Empowering Global Industrial Upgrading

Looking ahead, DNE Laser will continue to uphold the spirit of craftsmanship, increase R&D investment, and leverage its profound technological expertise and lean manufacturing processes to continuously iterate automated and intelligent laser equipment solutions. This award is not only a milestone for the company but also a new starting point. Building on the technological breakthroughs of the D-Cell unit, the company will further expand its application boundaries in high-end manufacturing, contributing to the global upgrading of China’s laser industry.

Source: DNE Laser