Han’s Laser: Han’s Laser Earns Multiple Honors with Innovative Strength at SRA2025 4th China Laser Star Awards

2025 Laser Star Awards Ceremony

On November 28, 2025, the 4th China Laser Star Enterprises Summit and Laser Star Awards Ceremony was grandly held in Wuhan. Laser industry experts, scholars, representatives of leading enterprises, and elites from growing companies across the country gathered together to share and discuss new ideas, new technologies, new products, new applications, and new trends, jointly promoting collaboration across the industry chain.

At this year’s “Laser Star Awards” selection, Lu Qitao, Chief Technology Officer of Han’s Laser, was honored with the “Laser Industry Outstanding Figure Award.” Simultaneously, through its persistent dedication in cutting-edge technological fields and a series of breakthrough achievements, its subsidiaries secured multiple major awards. Once again, this solidifies the company’s leading position on the global laser technology stage with its core strengths, injecting powerful momentum into the intelligent and high-end transformation of China’s manufacturing industry.

Laser Industry Outstanding Figure Award

Lu Qitao, Chief Technology Officer of Han's Laser

Best Fiber Laser Technological Innovation Award

Company Name: Shenzhen Han's Optoelectronics Laser Technology Co., Ltd.

Entry Product/Technology: 14/50 Dual-Beam Fiber Laser

Best Semiconductor Laser Technological Innovation Award

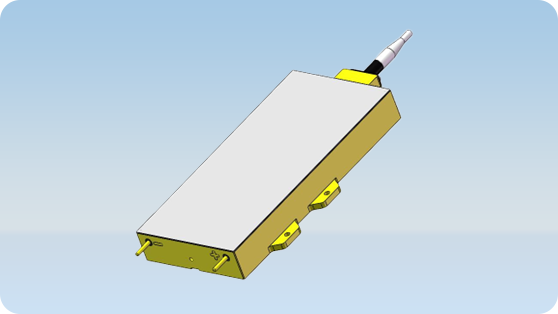

Company Name: Shenzhen Han's Laser Guangpu Technology Co., Ltd.

Entry Product/Technology: 420W 976nm Wavelength-Locked Semiconductor Laser

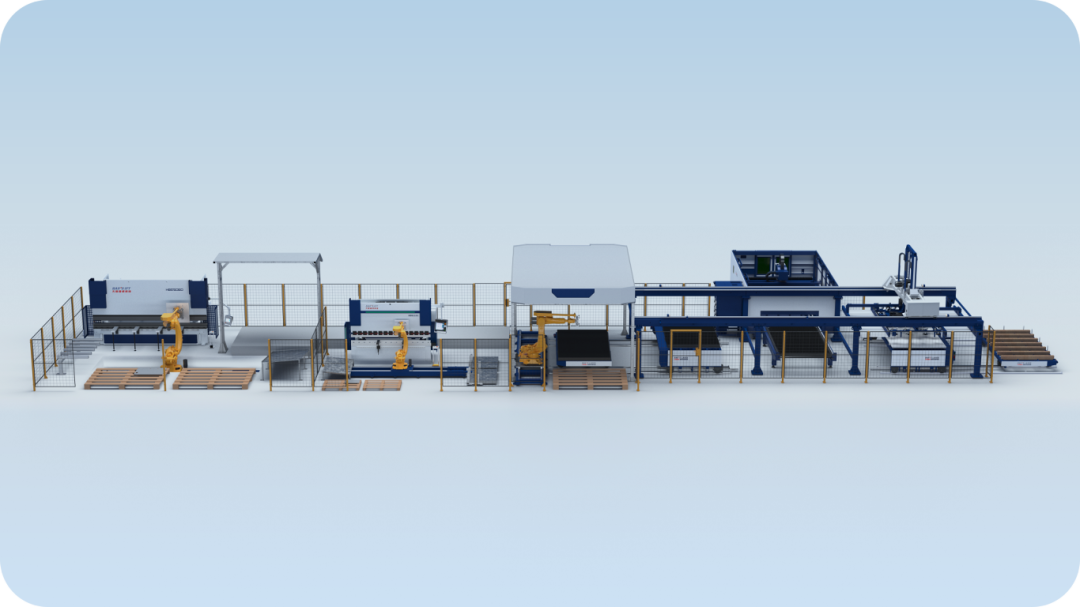

Best Laser Automated Production Line Technological Innovation Award

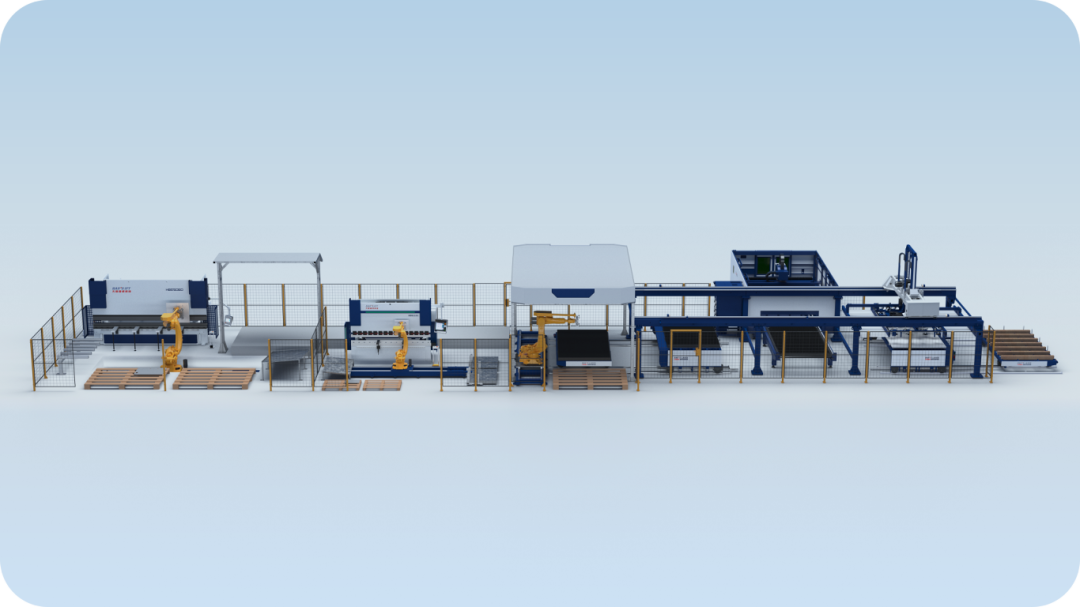

Company Name: Han's Laser Intelligent Equipment Group Co., Ltd.

Entry Product/Technology: MLU Series Laser Bending Flexible Automated Production Line

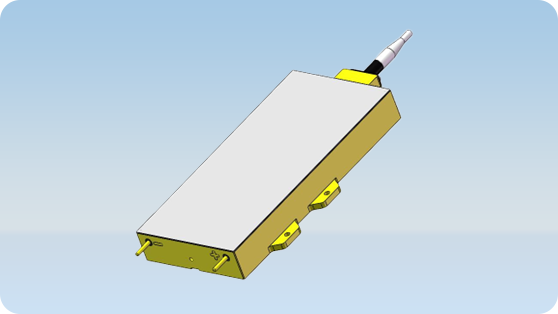

Best Laser Equipment Supporting Product Technological Innovation Award

Company Name: Shenzhen Han's Intelligent Control Technology Co., Ltd.

Entry Product/Technology: HAN'S801-BV Plane Laser Bevel Cutting CNC System

A Moment of Glory

The leap from “Made in China” to “Intelligent Manufacturing in China” hinges on breakthroughs in fundamental research and independent innovation capabilities. Laser technology, often regarded as the “universal tool” and “precision measuring stick” of modern manufacturing, directly influences the quality and efficiency of strategic emerging industries such as high-end semiconductors, new energy vehicles, aerospace, and advanced displays.

Han’s Laser consistently integrates the innovation gene into its corporate DNA, treating technological R&D as its lifeline. In the face of global supply chain uncertainties and the urgent domestic demand for high-end laser equipment driven by industrial upgrading, Han’s Laser continually engages in independent breakthroughs and leads at the technological forefront. At the SRA 2025 awards, Han’s Laser demonstrated excellence across multiple sectors including ultra-high-power laser cutting, core components, and intelligent production line solutions. Its award-winning projects showcase significant global competitiveness.

Award-Winning Product/Technology Showcase

14/50 Dual-Beam Fiber Laser

A new product in Han's Photonics "Tiangong" Series, this laser achieves precise control through free switching between Gaussian and spot-ring beams. It enables fixed spot-ring beam energy ratios for enhanced efficiency in large-scale part production during batch manufacturing, while also combining with ultra-fine spots to achieve high-precision forming of complex structures. This technology further breaks through the traditional trade-off between efficiency and fine detail.

420W 976nm Wavelength-Locked Semiconductor Laser

This pump module utilizes the ZEMAX optical design software to simulate a unique optical design and beam combination system. It couples the beam into an optical fiber with a numerical aperture of 0.22 and a core diameter of 200 μm, achieving an optical power output of 420W at the fiber end face. The high output power of 420W, combined with the 200μm output fiber, delivers excellent beam quality and uniform energy distribution. This meets the high energy density demands of various industrial processing applications, enabling more efficient operations. The module also features outstanding photoelectric conversion efficiency, effectively reducing energy consumption and lowering operational costs.

MLU Series Laser Bending Flexible Automated Production Line

This automated production solution is specifically designed to meet the demands of sheet metal intelligent manufacturing. It begins with raw material storage and seamlessly integrates the entire process of laser cutting, visual sorting, and bending forming. The entire workflow operates with high-efficiency coordination and full automation, with seamless transition between processes requiring no manual intervention. The production line deeply integrates intelligent sensing, machine vision, and industrial robotics technologies, establishing a complete intelligent manufacturing closed loop. It not only addresses the flexible production challenges of high-mix, low-volume orders but also enables 24/7 unmanned continuous operation through a high-precision vision system driven by deep learning algorithms and a modular equipment collaborative architecture. It provides manufacturing customers with a transformation and upgrade solution that combines high efficiency, cost-effectiveness, and scalability.

HAN'S 801-BV Plane Laser Bevel Cutting CNC System

Built upon a fully proprietary CNC kernel, this system adopts an Intel hexa-core high-performance CPU platform paired with a fanless, sealed-fin industrial computer for heat dissipation. It utilizes a high-performance five-axis machining motion control algorithm and integrates functions such as AB rotary axis control, RTCP programming, 3D trajectory simulation, and rapid bevel calibration. It can process various beveled workpieces with V-shaped, A-shaped, Y-shaped, and other cross-sectional bevels according to customer production requirements, ensuring stable and efficient performance.

Conference Forum & Outstanding Presentation

This summit brought together key leaders, distinguished guests, authoritative experts, and representatives from core enterprises within the laser industry chain. It deeply focused on the critical manufacturing processes of laser technology across multiple application fields, interpreted future industry trends, and helped enterprises accurately seize new development opportunities.

Guided by national strategies and closely aligned with market demands, Han's Laser consistently promotes the deep integration of laser technology with automation, informatization, and intelligent systems. Taking this forum as an opportunity, Han's Laser joined industry peers in gaining insights into cutting-edge technologies, innovative applications, and substantial achievements, pooling collective wisdom to jointly build a new ecosystem for intelligent manufacturing.

Against the comprehensive backdrop of China's "Dual Carbon" strategy, the green transformation of the manufacturing sector is no longer an "optional choice" but a "compulsory question" crucial for long-term development. In the keynote presentation titled "Switching to New Momentum: How High-Power Laser Thick Plate Cutting Becomes the Green Alternative to Plasma/Flame Cutting," Mr. Zha Congwen, Deputy General Manager of Han's Photonics, pointed out that in key industries such as heavy machinery, shipbuilding, and energy equipment, thick plate cutting—as a fundamental process—is undergoing a profound transformation in energy methods.

In response to this challenge, the high-power laser cutting solution launched by Han's Photonics emerges as a timely "green answer." It not only significantly enhances direct processing efficiency but also greatly reduces overall production costs by virtually eliminating secondary processing steps. Particularly important is that this solution offers multiple advantages, including low energy consumption, no harmful gas emissions, and significantly reduced noise and dust pollution. It can effectively help enterprises build green competitiveness and confidently meet future low-carbon requirements.

Traditional plasma and flame cutting technologies have made significant contributions in the past. However, their "three-high" characteristics—high energy consumption, high pollution, and high subsequent costs—have now become bottlenecks constraining the green upgrade of the industry. Dr. Zha Congwen's presentation clearly showed the audience how high-power laser thick plate cutting technology breaks through traditional manufacturing bottlenecks and its core value in promoting green manufacturing and facilitating the upgrade of the heavy equipment industry.

Winning multiple awards at SRA 2025 is both an honor and a new starting point for Han's Laser. Against the backdrop of increasingly fierce global technological competition, Han's Laser's achievements represent a microcosm of China's strategy for achieving high-level scientific and technological self-reliance and self-strengthening, greatly boosting the confidence of the national industry.

Advancing into deep waters, defining China's stature in global competition. In the future, Han's Laser will increase investment in R&D for frontier technologies such as ultrafast lasers, composite manufacturing, and intelligent photonics. It will continue to improve the integrated innovation of lasers with automation, digital twins, and industrial internet platforms. Simultaneously, it will inspire more Chinese technology companies to courageously venture into "uncharted territory," carving out more marks belonging to China on the journey toward the stars and the sea.

Source: Han's Laser