Media Spotlight on CIIF | Ringier's Industrial Laser : Insights on Intelligence and Green Sustainability from Laser Enterprises

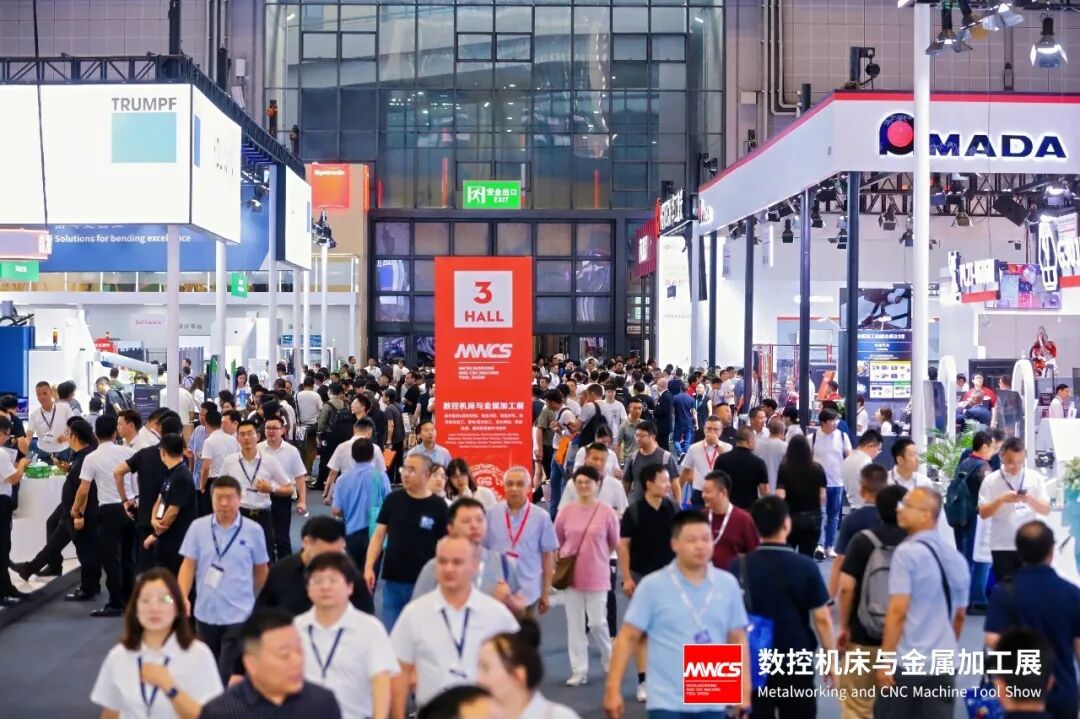

Last week, the 25th China International Industrial Fair (CIIF 2025) was held at the National Exhibition and Convention Center in Shanghai. Under the theme “New Industrial Quality, Intelligent Manufacturing Without Boundaries,” the event brought together over 3,000 exhibitors from 28 countries and regions. Alongside the exhibition, 10 high-level forums and nearly 300 thematic events were held.

During the fair, the Ringier editorial team visited the exhibition halls for face-to-face exchanges with numerous exhibitors. Through interviews, we gained insights into their development strategies and technology roadmaps. Notably, the equipment and products showcased consistently reflected themes of intelligence, green technology, and sustainability—aligning closely with China’s manufacturing vision of “New Quality Productive Forces.”

Part 1

Intelligent Solutions Unleashing Boundless Productivity

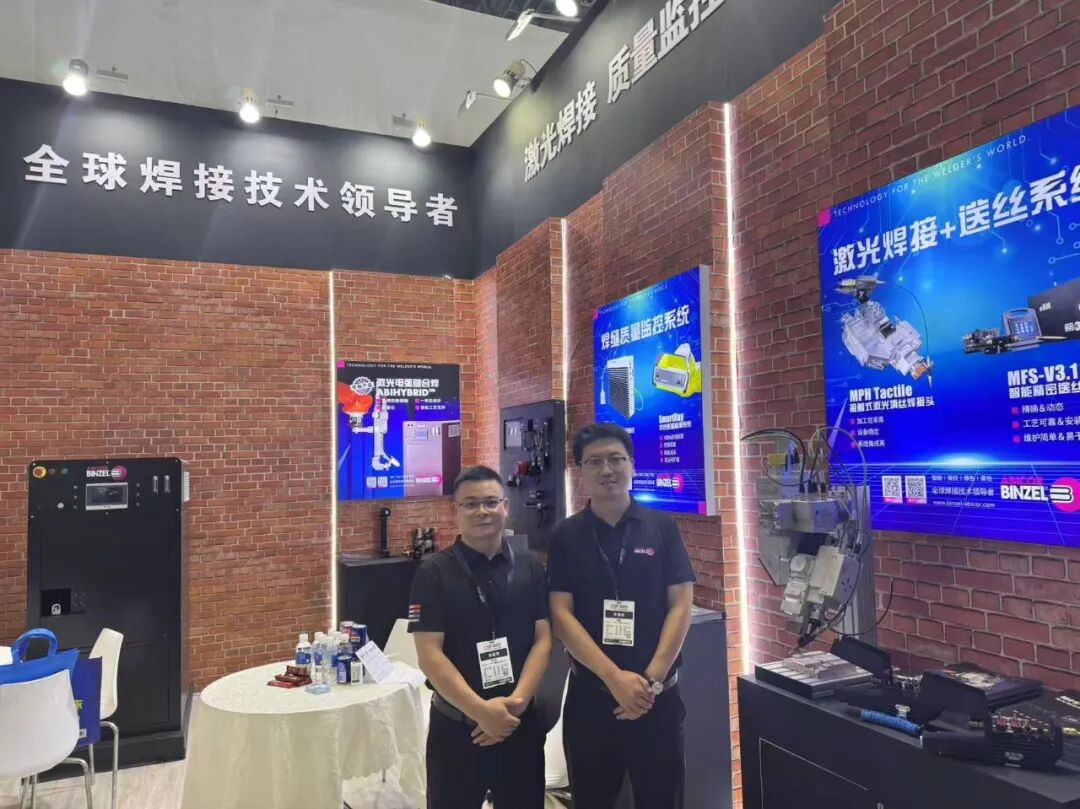

At this year’s CIIF, many companies highlighted “intelligent solutions” in their displays, responding to the industry’s growing demand for smart equipment. At the BINZEL booth, key products included laser wire-filling welding, laser brazing, laser hybrid welding, precision wire feeders, as well as weld process monitoring and post-weld quality inspection systems.

Among them, the MPH-T laser wire-filling welding equipment stood out with its optimized optical design, offering versatility for multiple applications across different industries. This reduces the need for spare parts and lowers user inventory pressure. The system also features state visualization, enabling real-time monitoring of temperature and contamination levels in the laser head’s optical lenses—providing clear insights into the condition of each lens. Additionally, with its design focused on quick maintenance, the MPH-T contact-type laser wire-filling welding system allows for 100% domestic repairs in China, significantly cutting downtime and repair costs for local users.

Laser Welding & Wire Feeding Systems Sales Engineer Peng Xiaofang (Left), Central China Welding Sales Engineer Lin Feng

The precision wire feeder is specifically designed and developed for laser welding and aluminum laser welding applications, featuring high stability and accuracy. It enables real-time monitoring of wire feeding speed and resistance changes, achieving state visualization for enhanced operational control.

We have launched a new generation of the 4D Welding Process Monitoring System, which incorporates 26+ signal variables. By leveraging different combinations of these variables, it effectively resolves issues of under-detection and over-detection, making it widely applicable in sectors such as gears, new energy batteries, fuel cells, and new energy motors.

The SmartRay Post-Weld Surface Quality Inspection System has gained the trust of numerous clients thanks to its highly accessible sensors, intelligent algorithms, and high-quality service. It is extensively used in inspecting automotive front and rear subframes, torsion beams, battery trays, motorcycle frames, and battery cells.

Addressing the industry's demand for high precision and integration in thin plate welding, the company has introduced the ABIHYBRID Laser-Arc Hybrid Welding System, which integrates the laser and control systems into a standardized workstation. The device employs a collaborative control architecture to synchronize the power supply and laser emitter, ensuring perfect alignment of input process parameters to achieve optimal welding results. The lightweight design of the welding torch (2 kg) meets the production requirements of most industrial robots. Additionally, the company's EWR2 Gas Saver helps customers reduce gas costs by up to 60%, offering easy operation and data recording capabilities.

At the TRUMPF booth, the company centered its display around the core theme of "YOU WIN"—emphasizing mutual success with customers—and showcased solutions for efficient and intelligent sheet metal processing through four key equipment exhibits. Among them, the innovative 5000 Series Punching Laser Machine TruMatic 5000 integrates laser cutting and CNC punching/forming, enabling finished parts to be produced directly from a single blank. This significantly reduces labor time and provides an ideal solution for small-batch, multi-variety production.

Versatile 5000 Series Bending Machine, embodying both "Versatility" and "Reliability", is equipped with a Dynamic Deflection Compensation system to ensure absolute accuracy across the entire bending length, maintaining stable precision even in batch production. Its intuitive operating system allows even beginners to get started quickly. Additionally, this machine is suitable for various processing scenarios, meeting the personalized needs of different customers.

Following bending comes the welding process. For this, TRUMPF's TruLaser Weld 5000 series automated laser welding system utilizes BrightLine Scanner technology combined with heat conduction welding, achieving excellent surface appearance with minimal deformation, thereby reducing grinding and shaping processes. This laser welding system enables a variety of weld types such as seam welding, lap welding, and penetration welding, offering flexible and diverse welding methods suitable for modern industrial applications involving multiple product types, small batch sizes, and imaginative designs.

Finally, making its "China debut" at this Industrial Fair is the fully automatic 7000 Series Panel Bending Center. From material retrieval and bending to stacking, this machine can operate entirely without manual intervention, achieving truly automatic, unmanned bending in one seamless process, delivering high-precision, high-efficiency bent products. With its flexible and intelligent features, the Panel Bending Center meets diverse production demands, significantly enhances bending efficiency and precision, and ushers in a new era of intelligent bending.

At this year's exhibition, the Bystronic Group showcased a dual-brand presence with Bystronic and DNE. During the event, the company launched the new ByCut series laser cutting machine and the new ByBend Smart series bending machine. The ByCut series laser cutting machine integrates the company's latest core technologies and innovations, offering higher performance, greater intelligence, and improved stability. It incorporates "Four Major Innovations": a new generation of self-developed SSC V3 high-performance cutting head, an innovative triangular-structure cutting bridge, a modular new bed frame, and an independent hydraulic control unit. Furthermore, it is equipped with advanced AI intelligent control functions, providing customers with an efficient, stable, and intelligent cutting experience.

Bystronic Booth

In addition to its patented technology (Dynamic Deflection Compensation), the new ByBend Smart series bending machine incorporates two additional groundbreaking innovations. The Light Angle Measuring System (LAMS) significantly enhances bending efficiency and accuracy, ensuring consistency and precision in bends. Meanwhile, the Heavy-Duty Adaptive Material Support function helps customers expand their production capabilities, facilitating the feeding of large and long workpieces.

Furthermore, the automatic loading and unloading solution ByLoader Flex and the compact bending automation solution ByBend Smart Mini have also garnered considerable attention. Both solutions have undergone comprehensive intelligent upgrades, offering not only excellent return on investment but also empowering customers to tackle diverse production challenges with higher efficiency and greater adaptability to various scenarios.

Coherent Gaoya primarily showcased its new series of fiber laser products at this Industrial Fair: the EDGE Series, AIM Series, and ARM Series, which are currently the company’s three flagship fiber laser offerings. All three series retain the advantages of Coherent’s traditional fiber lasers, featuring exceptionally high beam quality and ultra-stable performance. For processing ferrous and non-ferrous metals, these lasers offer outstanding anti-reflection capabilities, enabling customers to achieve superior processing quality without being affected by back-reflected light.

Building on the universal advantages of its laser technology, the company has further refined and specialized its designs for different application scenarios. For example, the EDGE Series is a laser specifically engineered for the sheet metal cutting market, where the laser source and cutting head form an integrated subsystem. This series seamlessly incorporates Coherent Gaoya's extensive portfolio of fibers, coupling devices, and process control optics, providing customers with a comprehensive laser cutting solution.

The ARM Series represents the company’s most classic ring-mode laser system. In addition to the earlier single-core single-ring ring-mode laser, this exhibition also features a single-core dual-ring ring-mode laser. This laser retains the core technological advantage of independent control, allowing both the core and the ring to be controlled separately. With this technology, customers can precisely control the dynamics of the molten pool, ensuring production stability and process consistency.

Part 2

The Inevitable Trend of Artificial Intelligence

Regarding the impact of artificial intelligence on the future of the industry, Li Ming, Sales Director of TRUMPF East China, shared that AI represents a new milestone in industrialization. TRUMPF has conducted extensive research in this area and achieved significant results. For example, in laser cutting, the TRUMPF 5000 Series laser cutting machine features intelligent cutting capabilities. The cutting process utilizes graphic monitoring for real-time processing—when rust spots or other obstacles are detected, the machine automatically increases power and reduces cutting speed without any manual intervention. This AI-driven operation is built on big data integration, enabling rapid computation and optimal decision-making.

Trumpf Booth

Additionally, through smart factory solutions, users can process multiple product types in small batches at the cost of mass production. This is another contribution TRUMPF has made to the industry through AI. In the future, with continuous R&D and investment, the company will provide even more competitive solutions for the industry.

Dr. You Song, President of Bystronic Group for China and Asia Pacific, believes that from a technical perspective, the company has always focused on deepening product expertise and advancing intelligence. This includes long-term product innovation, production line automation, and smart factory transformation, all of which remain core directions for the company's development. To this end, Bystronic has established dedicated automation technology and software companies. The recent implementation of automation solution projects further demonstrates Bystronic's capabilities in production line automation and smart factories. By integrating hardware and software, the company ensures seamless connectivity across all stages, enabling perfect fusion of materials and data. This allows customers to truly achieve flexible and intelligent production in sheet metal processing. At the same time, Bystronic remains committed to green innovation, sustainable development, energy conservation, and environmental protection, implementing innovative measures from product design concepts and supply chain systems to product usage and energy consumption.

Today, meaningful innovation lies in fully leveraging AI, big data, robotics, and machine learning, and integrating them seamlessly with established processing equipment, manufacturing processes, and control systems. Taking the AI-enabled laser cutting machine showcased by the company at this exhibition as an example: with a camera embedded inside the cutting head, it enables full-process predictive simulation of the cutting operation and proactively prevents potential issues. These functionalities exemplify product intelligence, elevating the technology to a new level.

During the interview, Ye Chuangbo, Head of Brand Operations at Han's Laser Group, discussed that with the rise of the AI wave, servers and high-speed switches require higher-layer, higher-density, high-speed multilayer PCBs to support them. To ensure signal integrity in high-speed PCBs, stricter demands are placed on hole quality, circuitry, and final product standards. In response, the company has keenly identified this key trend of technological advancement and is actively accelerating product innovation in the fields of high-layer-count multilayer boards and high-layer-count HDI.

Thanks to a high degree of technical synergy with downstream clients, the company’s market position has significantly improved. At the same time, in high-end fields such as substrate-like PCBs and IC packaging substrates, the company has taken the lead in launching new laser solutions. These solutions have quickly gained certification from leading industry customers and rapidly translated into orders, further solidifying the company’s technological leadership.

Moreover, the global electronics industry chain’s “China+N” strategy has spurred the expansion of PCB production capacity in regions such as Southeast Asia. Han’s Laser has actively adapted to this shifting industrial landscape, leveraging its overseas teams to explore incremental markets and inject new momentum for sustained future growth. Through this series of initiatives, the company is gradually transitioning from a traditional PCB equipment supplier to a provider of high-value-added technological solutions, securing a first-mover advantage in the wave of AI-driven industrial upgrading.

Huang Jiandong, General Manager of Salvagnini China, stated that as a strategic technology driving a new wave of scientific and industrial transformation, artificial intelligence can address a series of weaknesses in traditional manufacturing, such as low efficiency and high costs. It propels the industry toward higher-end and smarter transformation, aligning with the current transition trend of most sheet metal factories. As a global benchmark in flexible sheet metal processing technology, Salvagnini continues to integrate cutting-edge technologies with its own equipment and expertise, providing more advanced and high-quality solutions for clients across various industries.

Salvagnini Booth

Taking the P-ROBOT solution integrated with the RVS system showcased by the company at this Industrial Fair as an example, within this solution, Salvagnini has equipped the robotic arm with the RVS 3D artificial vision system, embedded with advanced AI algorithms. This ensures that the system can accurately identify workpieces from unordered stacks without the need for physical references, successfully simplifying workpiece recognition operations and automating intermediate steps. While making the production process faster and more intuitive, it also effectively enhances the overall solution, enabling compatibility with various upstream and downstream processes. By using the RVS-integrated P-ROBOT as the core in a modular approach, it helps build intelligence across the entire factory.

Part 3

Rooted in China, Eyes on the Global Landscape

In July of this year, Bystronic Group's China headquarters was officially recognized and upgraded by the Ministry of Commerce to serve as its Asia-Pacific headquarters. Discussing future development, Dr. You Song stated that moving forward, the company will adopt a "China-centric" strategy, radiating its influence across the Asia-Pacific region and the world—a significant move for the Swiss Bystronic Group. He expressed hope that products designed in China will, in the future, support global markets in reverse—not only in developed markets like Europe and America but also in Asia-Pacific, South Africa, and South America.

To foster better growth, the company has also established a "16-Character Guiding Principle" for its operations: Digital Leadership, Deep Cultivation, Product Excellence, and Service First.

Digital Leadership refers to driving digital and intelligent smart factory solutions.

Deep Cultivation means optimizing the company's operational supply chain and manufacturing efficiency to the utmost.

Product Excellence embodies the Swiss craftsmanship spirit, ensuring the company’s products earn full recognition from customers in the market.

Service First entails promptly addressing customers' operational challenges, prioritizing their urgent needs, and anticipating their expectations.

Dr. You Song expressed his hope that the synergistic development of the Bystronic and DNE dual brands would truly achieve the "Dual-Engine Drive" strategy for the Bystronic Group in the future. After years of development, DNE Laser has reached a stage requiring breakthrough growth. The Group hopes that DNE Laser can fully leverage global opportunities to expand internationally and become a prominent international brand. With the company's significant strategic adjustments, along with continuous updates and iterations in product solutions and technology, Bystronic China and Asia-Pacific are confident in maintaining the strong growth momentum seen in the first half of the year, despite current market uncertainties. The company aims to lead the industry and contribute to the intelligent transformation of China's manufacturing sector.

During the interview, Ms. Shao Feng, Strategic Marketing and New Product Expansion Manager for Coherent Gaoya's laser business, highlighted that as a company with fully vertically integrated capabilities across the entire industrial chain—from lasers and cutting heads to scanners and optical lenses—the collaborative design and manufacturing of products across the chain allow customers to benefit not only from product advantages but also from long-term cost control.

Currently, the company is not only bringing its global innovation experience to China but also integrating it with local practices. In addition to introducing innovative expertise, Coherent Gaoya has established local R&D teams and a robust application support team in China. The company also places great emphasis on developing local manufacturing and supply chain capabilities to ensure long-term market competitiveness. As a global leader in laser innovation technology, Coherent Gaoya is committed to providing Chinese customers with world-class, tailor-made technical solutions, helping them achieve success not only in the domestic market but also on a global scale.

END

Source: Ringier Industrial Laser